1. Product description

Axial joints similar to DIN 71802 are mechanical linking elements that allow for linear motion transmission along an axis. They typically consist of a axial ball socket similar to DIN 71805 and a ball stud DIN 71803, which are connected in a straight line. The possible swivel angle is comparable to DIN 71802 at ±18°, and the extraction forces of the ball stud from the ball socket range from a minimum of 30 to a minimum of 100 N, depending on the size. This construction is particularly suitable for applications requiring precise and linear force transmission. Axial joints are often used in areas such as linear drives, lifting systems, and wherever direct force transmission in an axial direction is needed. They offer high reliability and stability for various industrial applications.

The main difference between angle joints according to DIN 71802 and axial joints similar to DIN 71802 lies in their design, their different force transmission (90° for angle joints and 180° for axial joints) and their areas of application:

Angle joints according to DIN 71802:

Form and structure: Angle joints have an L-shaped, right-angled construction. They generally consist of a ball socket and a ball stud, forming a 90-degree angle.

Direction of movement: Angle joints primarily enable the transmission of motion at an angle. They are ideal for applications where a change in the direction of force or movement is required.

Application area: Angle joints are frequently used in mechanical systems where motion transmission occurs at a specific angle, such as in pull and push rods.

Axial joints similar to DIN 71802:

Form and structure: Axial joints are primarily designed for the transmission of motion along an axis. They typically have a straight, line-like construction.

Direction of movement: Axial joints transmit forces and movements along a straight line, along the axis of the joint. This means they are suitable for applications requiring linear motion.

Application area: Axial joints are used in applications that require linear motion transmission, such as in linear drives or lifting systems.

In Summary:

Angle joints according to DIN 71802 offer right-angled motion transmission and are suitable for applications where a change in the direction of movement is needed.

Axial joints similar to DIN 71802 provide linear motion transmission along an axis and are suitable for applications that require linear movement.

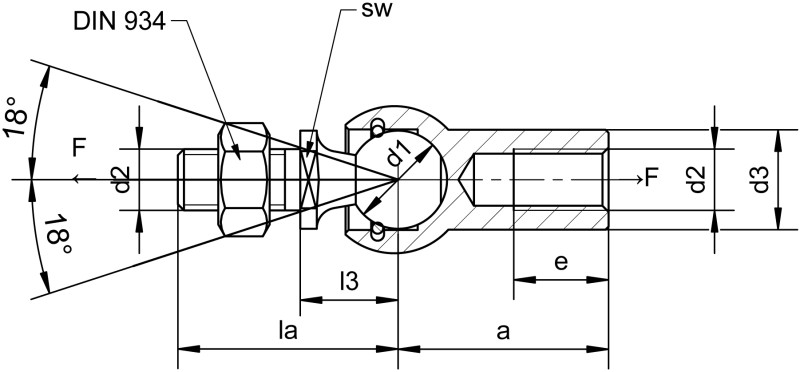

An axial joint is also an assembly. The following list describes the individual parts of the classic version similar to DIN 71802:

- Axial ball socket similar to DIN 71805

The axial ball socket surrounds the ball stud and allows unrestricted movement in all directions. Its precise manufacturing ensures low-friction function and long-lasting stability. - Ball stud DIN 71803

The ball stud features an external thread and a spanner surface for easy mounting. It is inserted into the axial ball socket and ensures the necessary mobility of the joint. - Circlip

This ring securely holds the ball stud in the axial ball socket and prevents accidental detachment. - Sealing cap (optional)

Protects from dust, dirt, splashes, and vapors, extends the lifespan of the joints, and reduces maintenance requirements. - Hex nut DIN 934

For fastening and additional securing of the ball stud. - Grease

To reduce friction between the ball stud and the axial ball socket and to extend the lifespan of the joint.

2. Product details

Size: 6 M4 - 19 M16

Material group: Steel, stainless steel, stainless steel A4 quality

Surface: bright, electr. galvanised white

Thread version: Regular thread right and left, fine-pitch thread right

d2 Thread: M4 x 0,7 - M16 x 2

Threads: Generally, the standard versions of the axial ball socket are equipped with a right-hand thread. Each size is assigned an appropriate thread size according to the standard. Deviating from this, different thread sizes or a metric left-hand thread are also possible, provided the part geometry allows it. Additionally, for applications requiring a more precise adjustment option, the component can also be designed with a fine-pitch thread with a smaller pitch.

Swivel angle: The swivel angle of axial joints similar to DIN 71802 is ±18 degrees. This means the joint allows for a total movable rotation of 36 degrees, ensuring the joint offers sufficient flexibility to compensate for axial movements and alignment errors in applications.

Pull-off forces: The pull-off forces of the ball pin, as encountered in axial joints similar to DIN 71802, range between a minimum of 30 and a minimum of 100 N, depending on the size. These values indicate the amount of force required to pull the ball pin out of the axial ball socket. These pull-off forces are crucial for stability and safety, ensuring the connection remains secure under normal operating conditions and does not inadvertently come loose, guaranteeing safe power transmission and motion control.

3. Application Areas & Compatibility

Axial joints similar to DIN 71802 are used in a variety of industrial and mechanical applications where precise linear movements and power transmissions are required. Here are some specific application areas:

Mechanical engineering: In many machines and systems, axial joints are used to transmit movements and forces precisely. They are applied in various machine elements, such as sliding mechanisms and lifting systems.

Automotive engineering: Axial joints are used in vehicles to convey movements in steering and suspension systems. They enable precise control and stability of vehicle movements.

Agricultural and construction machinery: In heavy machinery, such as tractors and excavators, axial joints are used to transmit forces and movements in hydraulic systems and other linear drives.

Energy technology: In power plants and energy facilities such as wind and solar farms, axial joints are used for controlling and transmitting forces and movements.

Manufacturing industry: In automated production lines and manufacturing facilities, axial joints are used for controlling and transmitting forces necessary for the movements of workpieces and machine components.

These versatile applications show that axial joints similar to DIN 71802 play an indispensable role in many areas to ensure precise and reliable motion and force transmissions.

Compatibility

Material choice: Axial joints are available in various materials, such as steel and stainless steel. The choice of material should be compatible with the environmental conditions (corrosion, temperatures, etc.) and the application specifications of the rest of the system or machine.

Sizes and tolerances: The dimensions of the axial joints must match those of the application systems. This includes diameters, lengths, and tolerances. Deviating measurements can lead to misfits and malfunctions.

Load capacity: Axial joints must withstand the loads and forces that occur in the application. It is important to know the maximum static and dynamic loads and ensure that the joint meets these requirements.

Compatibility with connectors: The ends of the axial joint must fit the connectors or further components that are combined with the joint. Different thread types or sizes can lead to compatibility issues.

Environmental conditions: Temperature, humidity, dirt, and chemicals can affect the performance and lifespan of an axial joint. Choose a joint designed specifically for the given environmental conditions.

Rotation angle and freedom of movement: Ensure that the axial joint offers the required rotation angle and necessary freedom of movement to perform the intended movements without restrictions.

Standards and specifications: Observe the relevant industrial standards and specifications that apply to your application. Axial joints similar to DIN 71802 should comply with the corresponding standards to ensure compatibility with other components and legal requirements.

4. Advantages and Benefits

Precise force transmission: Axial joints ensure precise linear force transmission along an axis, which is particularly important for applications where accuracy is required.

Flexibility: They offer high flexibility in movement, making them ideal for applications that require movement in multiple directions.

Robustness and durability: Made from high-quality materials such as steel and stainless steel, axial joints are robust, wear-resistant, and offer a long service life, even under difficult environmental conditions.

Versatility: Thanks to their various designs and sizes, axial joints can be used in a variety of applications, from mechanical engineering to medical technology.

Easy installation and maintenance: With their standardized dimensions and designs, axial joints can be easily integrated into existing systems. Additionally, they are maintenance-friendly, making operations more efficient.

Compact design: Their compact design enables use in confined spaces and contributes to space savings in the application.

Corrosion resistance: Stainless steel models are particularly corrosion-resistant and therefore ideal for applications in humid or aggressive environments.

Cost efficiency: Due to their durability and lower maintenance needs, axial joints often offer a cost-efficient alternative for many industrial applications.

These diverse advantages make axial joints similar to DIN 71802 an excellent solution for a wide range of technical challenges and applications.

5. Assembly and Installation

Preparation:

- Tools: Prepare all necessary tools, such as wrenches, torque wrenches, and any required special tools.

- Cleaning of parts: Ensure that all parts to be assembled are clean and free from impurities.

- Check material compatibility: Ensure that the materials of the axial joint and the parts to be connected are compatible to avoid corrosion or material failure.

- Lubrication: If required, apply an appropriate lubricant to the threads and other sliding surfaces to ensure smooth assembly and movement.

Assembly of the axial joint:

- Thread connections: Screw the male thread on the ball stud of the axial joint into the corresponding mating piece (e.g., a threaded hole) and connect the female thread on the axial ball socket with the other part to be connected (e.g., a threaded rod). You can use a torque wrench to avoid exceeding the recommended tightening torque and to prevent damage to the threads.

- Adjusting: Precisely align the axial joint in the desired position to ensure it corresponds to the correct angles and alignments.

- Check freedom of movement: Test the axial joint for its degrees of freedom and mobility. Ensure that it can move freely and without resistance in all required directions.

- Locking: If the axial joint needs to be fixed in a certain position, use appropriate locking means, such as locknuts, without impairing the freedom of movement.

Final inspection:

- Inspection: Examine the assembly for any irregularities, such as unusual resistance or play in the connections.

- Trial run: Perform a trial run to ensure that the axial joint operates correctly under load.

- Assembly record: Document the assembly, including the applied tightening torques, lubricants, and any adjustments, for future maintenance or repair works.

This structured approach ensures that axial joints similar to DIN 71802 are correctly and efficiently assembled, optimizing their performance and lifespan.

6. Safety instructions & Standards

Personal protective equipment (PPE): Ensure that you wear appropriate personal protective equipment, including safety glasses, gloves, etc.

Tool use: Use only appropriate, defect-free tools to avoid injuries and damage.

Lubrication and maintenance: Axial joints require regular lubrication and maintenance to function properly. Ensure that the lubricants used are compatible with the joint's material and check the maintenance requirements.

Service life and number of cycles: Check the service life and the maximum number of load cycles that the axial joint can withstand to ensure it is suitable for the planned duration and frequency of use.

Mechanical load: Never exceed the maximum static and dynamic loads of the axial joint. Overloading can lead to joint failure and thus dangerous situations.

Inspection before commissioning: Before commissioning the assembled system, a thorough inspection for correct installation and proper function of the axial joint must be conducted.

Maintenance intervals: Adhere to maintenance intervals and conduct regular inspections to detect wear or damage early.

Environmental influences: Consider the operating environment, particularly temperature, humidity, and chemicals, which could affect the performance and safety of the axial joint.

Standards

DIN 71802: Axial joints are similar to DIN 71802. This standard specifies the dimensions and technical requirements for axial joints to ensure a uniform fit and interchangeability.

DIN 71803: Ball studs DIN 71803 are an essential component of axial joints. The standard defines all important dimensions and technical details for this component.

DIN ISO 2768: This standard specifies general tolerances for lengths and angle dimensions as well as for form and position tolerances and is important for manufacturing precision.

DIN EN ISO 9001: This quality management standard ensures that operational processes, including the manufacturing and assembly of axial joints, are conducted efficiently and without errors.