Special screw production at mbo Osswald

Special screws are unique screws that are manufactured for very specific applications or special requirements. They can have different shapes and sizes and are made from various materials. They are used in various industries such as the automotive industry, aerospace, or mechanical engineering.

We are experienced in the production of special screws and manufacture them according to your individual specifications or drawings. The bolts, screws, or nuts can also receive special coatings or surface treatments. Learn more about our services and technical capabilities.

Applications of special screws of all types

Not only in the automotive industry, but especially there, astonishing developments are taking place, for example in terms of electrification. New drives, new systems and special technology also require special design and consequently fastening solutions. Custom screws and special nuts are the best examples of this.

In the aerospace industry, it is similar, and likewise in modern mechanical engineering. The production of custom screws affects several industries that are undergoing transformation, supporting progress and innovation. This also pertains to medical technology and especially the vast field of energy and environmental technology. By using two of these examples, we clarify the application of our products in more detail.

Medical technology

In medical technology, special screws are used for the production of medical devices and implants which have special requirements for hygiene, biocompatibility, and precision.

Energy and environmental technology

In industries such as power generation and environmental technology, special screws are needed for the assembly of power generation facilities, wastewater treatment, wind turbines, and solar collectors.

Processing areas and materials in special screws manufacturing

We strive to offer as broad a portfolio as possible, thus providing you with maximum freedom in selecting special screws, bolts, and nuts. For this, we have specific guidelines regarding the areas in which we manufacture these items for you.

Various shapes and lengths for any quantity

When it comes to round objects, we supply special screws and the like with diameters from 4 mm to 65 mm. In terms of the respective length of the screws or bolts, our options range from at least 5 mm to 350 mm. This allows for numerous applications and connections, such as in vehicles and machinery.

Simply let us know the exact quantities you need for your requirements. We are also very flexible with the numbers and achieve very high quantities with our efficient special screw manufacturing. Depending on the type, effort, and scope, we are happy to handle small, medium, and large series for you.

The most common materials: Steels of variable quality

Our experience and demand have led us to stock various types of steel in very large quantities. Primarily, undercut steel, stainless steel A2, and stainless steel in A4 quality are often processed and provide an excellent basis for many of our products. Special bolts, however, can also be made from other steels that we select based on specific properties:

- high strength

- corrosion resistant

- seawater resistant

- high-temperature

Special turned screws, special turned nuts – processing options

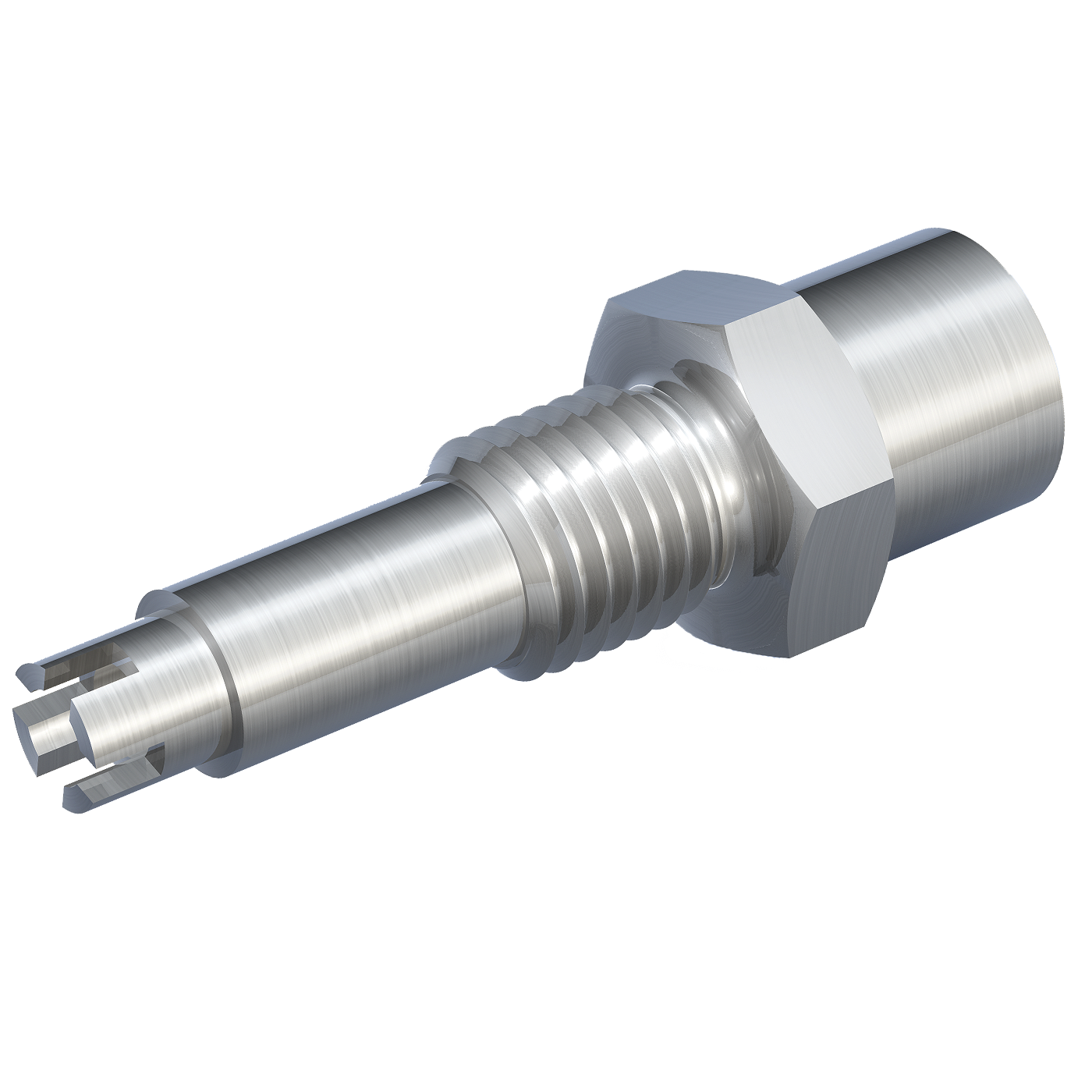

Special screws offer a variety of possibilities to customize them and adapt to the specific requirements of a project. This includes, among other things, cross holes, grooves, or various milling. The range of possibilities expands even further with various thread types.

Selection of processing options:

- Polygon turning

- Spanner surface

- Internal hexagon

- Thread types:

- metric or inch thread

- regular, fine-pitch and left hand thread

- Complicated geometries

Furthermore, special screws can also be individually marked to allow for easy identification. With these diverse design options, special screws are the ideal solution for demanding applications where standard products are insufficient.

Various surfaces for your special screws

How should the workpiece be designed and treated in the end? This depends greatly on the usage. For example, if the special screws are used in humid environments, they must be protected against water ingress. This can be achieved with techniques like electro-galvanizing. There are numerous ways in which we can post-treat the end products for you.

Coating

Besides special surfaces, we are more than happy to perform the aforementioned electroplated galvanizing for you. This process applies a thin protective layer of zinc on the workpiece's surface, acting as a barrier to protect the underlying metal from penetrating water.

Treatment

Another form of treatment comes from handling oils, greases, and the like. It may be sensible to keep the surfaces completely oil-free, or a defined oil film may be applied. This entirely depends on your wishes and the subsequent use.

Finishing

The finishing of surfaces refers to the targeted modification of properties through various processes such as heat treatment, coating, or finishing. In our special screw production, there are primarily three common variants:

- Grinding: In this mechanical processing method to produce smooth surfaces, we (mechanically) remove material using grinding bodies.

- Tempering: Through heat treatment processes, the hardness and strength of metals are improved. This is achieved by controlled heating and rapid cooling.

- Nitrocarburizing: In this thermochemical surface treatment process for steel, nitrogen and carbon are diffused into the surface. This increases the steel's hardness, wear resistance, and corrosion resistance.

The special bolts and custom screws at mbo Osswald

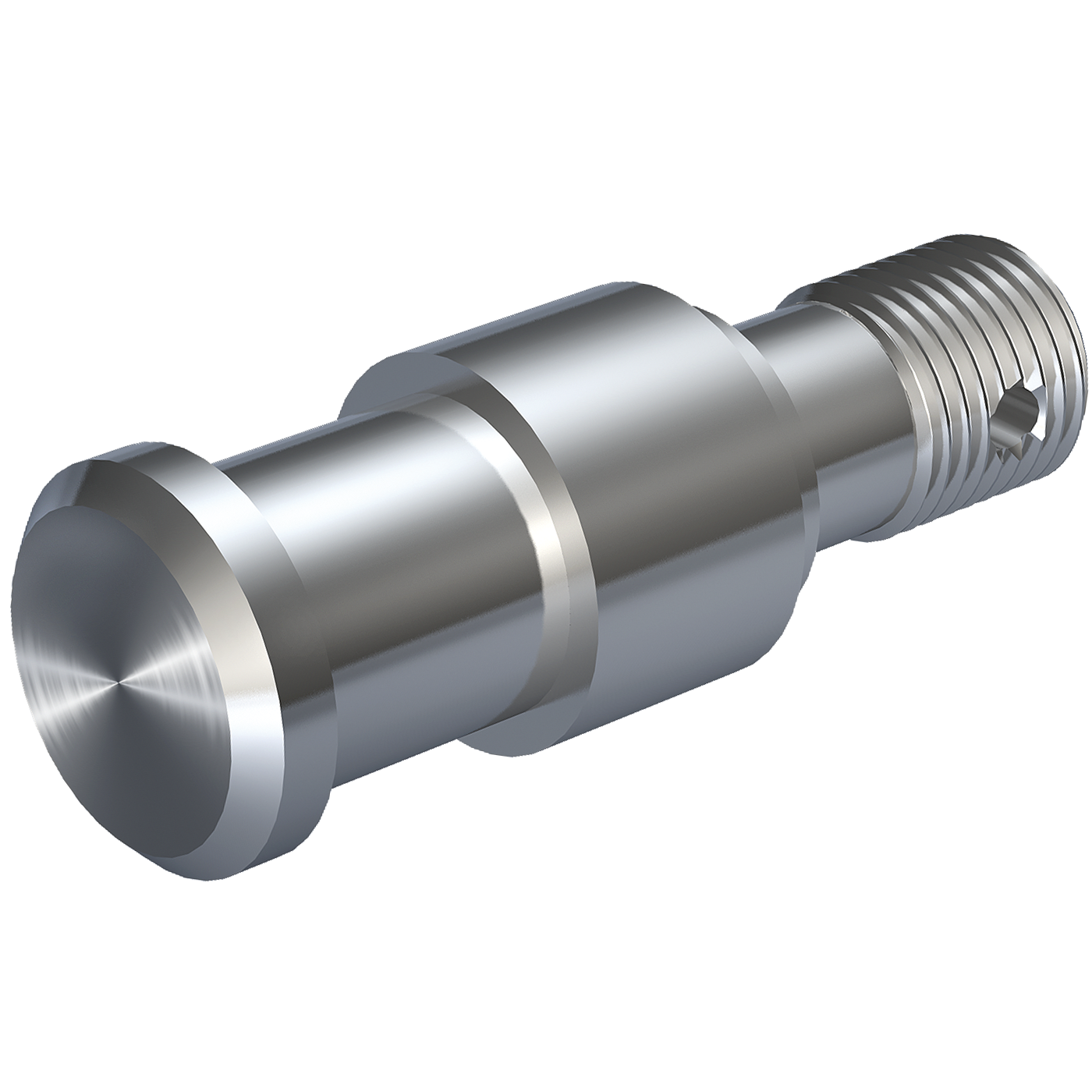

mbo Osswald offers you an impressive manufacturing diversity and produces a wide range of products, including housing screws, eye bolts, retaining bolts, special screws with hexagon socket and spanner surface, as well as threaded bolts with hexagon.

Furthermore, turned special screws and special nuts are manufactured according to individual specifications. This variety enables offering customized solutions for a wide range of requirements and applications, allowing for the production of both standard and highly specific components.

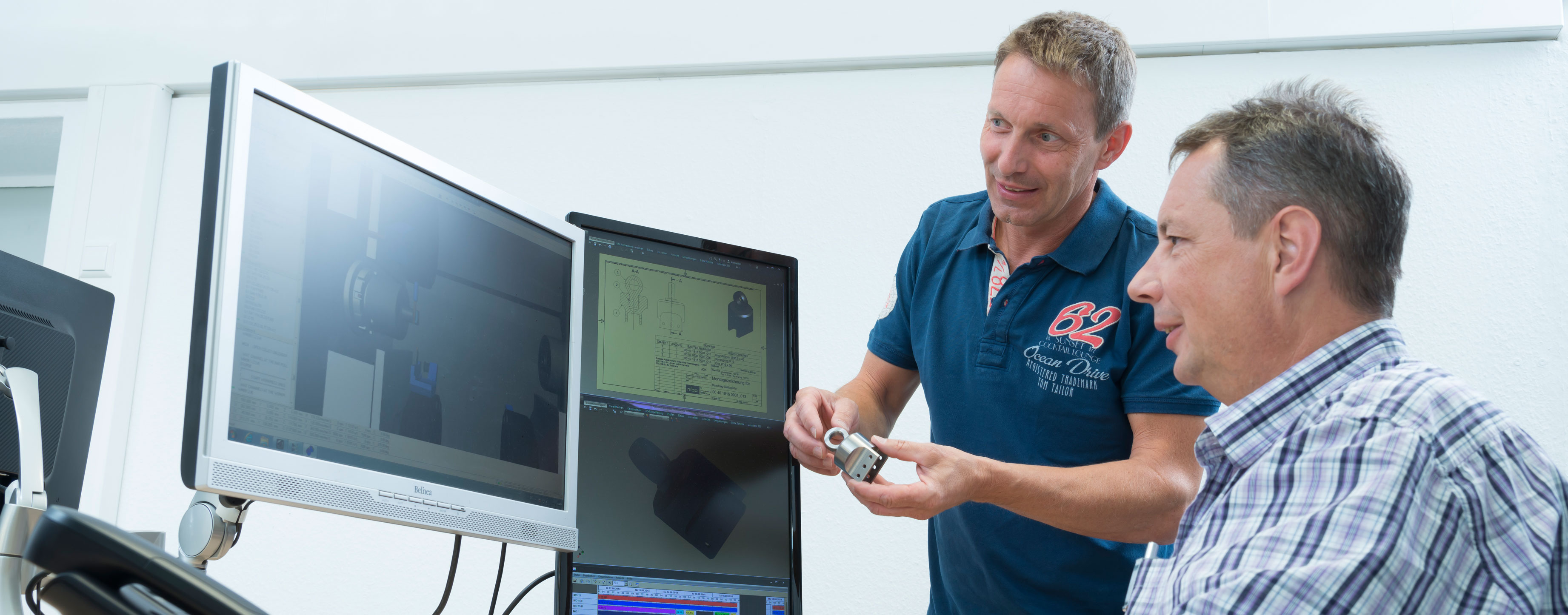

Specialist in special screw manufacturing: Production according to your Individual specifications

We produce custom-made screws and special screws according to your sample or drawing. Technically sophisticated production processes ensure compliance with product features and your requirements. With decades of experience in manufacturing highly complex, ready-to-install automatic turned parts and milled parts, we offer you full service.

This applies to all phases: from receiving your specifications to production and logistics. Everything from a single source in the required quality, quantity, and at your desired delivery date. And if you wish, we also take care of the assembly, packaging, labeling, and stocking of components according to your specifications.

Special screws are customized screws that are manufactured according to individual specifications, patterns, or drawings. They are used in applications that have specific requirements regarding shape, material, and function.

mbo Osswald primarily uses undercut steel, stainless steel in A2 and A4 quality, as well as other corrosion-resistant, seawater-resistant, heat-resistant or high-tensile steels.

The company offers turning, cross-holes, grooves, milling, polygonal turning, spanner surfaces, internal hexagon, and various types of threads (metric, inch, regular, fine-pitch, and left-hand threads).

The screws can be electroplated galvanized, provided with special surfaces, treated to be oil-free or with a defined oil film, as well as ground, hardened, or nitrocarburized.