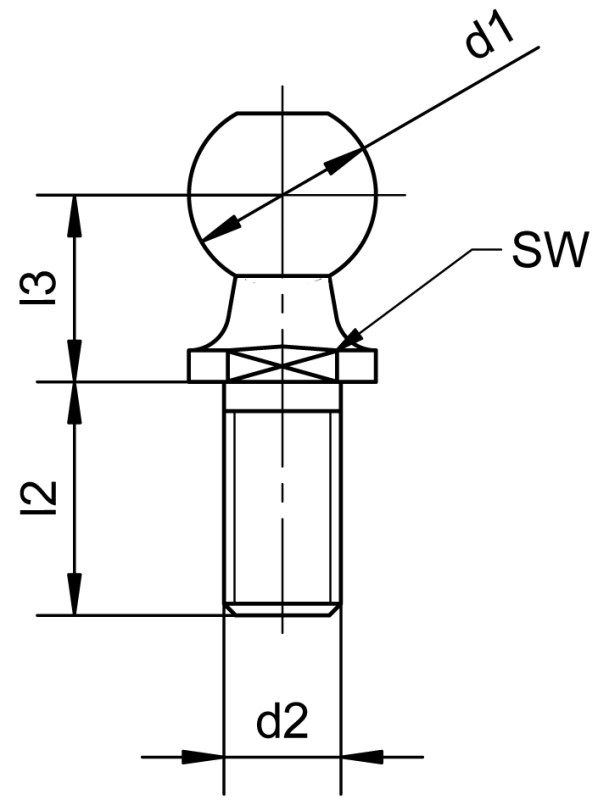

商品信息 "球头销 DIN 71803 C 型,带螺柱和球座扳手表面"

Ball stud

Ball studs according to DIN 71803, combined with ball sockets according to DIN 71805, form angle joints according to DIN 71802. Ball studs are available in all possible variations, with thread or as rivet stud, with or without spanner surface.

mbo Osswald's standard programme features sizes 6 to 19 with threads M4 to M16 in steel and stainless steel.

Frequently Asked Questions (FAQ)

What are ball studs according to DIN 71803 form C?

Ball studs according to DIN 71803 form C are mechanical linking elements with a threaded stud and a sphere-shaped head, allowing for flexible and precise movements in ball sockets. When mounted with a ball socket according to DIN 71805, ball studs according to DIN 71803 form a angle joint according to DIN 71802. Ball studs are also available in form B as rivet studs.

What materials are used for ball studs?

Ball studs are made of steel, stainless steel, and stainless steel in A4 quality.

What is the surface finish of the ball studs?

The surfaces of the ball studs can be bright or electr. galvanised white.

What types of threads are available?

Ball studs are available with both fine-pitch thread (right) and regular thread (left and right).

What sizes are available for ball studs DIN 71803?

The sizes for ball studs according to DIN 71803 vary depending on the application area, and can be ordered in various diameters and lengths. The exact dimensions are detailed in the standard and in the mbo Osswald eShop, and can be tailored to specific requirements.

Can ball studs be manufactured as custom-made products?

Yes, in addition to the standardized ball studs according to DIN 71803, mbo Osswald also offers the possibility to manufacture ball studs in custom designs according to specific customer requirements. Please feel free to contact us for this.

What are the applications of ball studs in mechanical engineering?

In mechanical engineering, ball studs are used in linking elements and joints for control and power transmission in various machines such as machine tools and conveyors.

How are ball studs used in vehicle construction?

In vehicle construction, ball studs are crucial for steering linkages, suspension components, and other moving parts that ensure stability and safety.

What advantages does the standardization according to DIN 71803 offer?

Standardization ensures high compatibility with other standardized components, facilitates replacement and integration into existing systems, and ensures consistently high quality.

What steps should be considered when assembling ball studs?

Before assembly, all components should be clean and free from contaminants. The ball stud is inserted into the appropriate ball socket and fixed in place by the snap ring in the socket.

Why is complying with torque important?

A correct torque when screwing prevents overload and damage to the components and ensures a secure fastening.

What quality controls are performed for ball studs according to DIN 71803?

Ball studs are subject to strict quality controls to ensure high product quality. These include material testing, dimensional checks, and surface inspections to ensure that the products meet high standards and specific customer requirements.