1. Product description

Axle holders according to DIN 15058 serve as essential mechanical machine elements for the precise fixing and positioning of axles or shafts within various machine constructions and types of equipment. Their main function is to prevent slipping and unintentional loosening of axles, shafts, or bolt connections during operation, thus enabling consistent and trouble-free transmission of rotational movements and forces. In combination with bolts, axle holders play an even more critical role by ensuring a firmly defined axle position and thus guaranteeing the integrity of the entire assembly. The axle holder is a rectangular metal strip that is fixed with two fastening screws and engages in a circumferential groove in the bolt. If the bolt is also to be secured against rotation, a tangential groove is milled into the bolt. The use of these components not only increases the precision and efficiency of mechanical processes but also significantly contributes to the longevity of the application. The precise alignment and fixing achieved by DIN 15058 axle holders minimize mechanical wear and improve the reliability of the application.

2. Product details

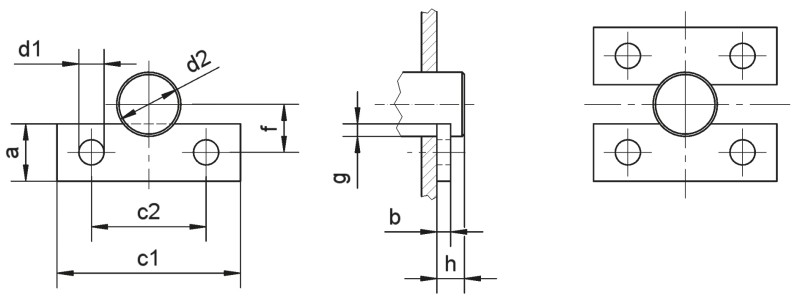

Size: 20x5x60 - 60x16x250

Material group: Steel, stainless steel

Surface: bright or electr. galvanized white

d1 Hole diameter: 9 - 25

c1 Length: 60 - 250

c2 Hole spacing: 36 - 200

b Height: 5 - 16

3. Application Areas & Compatibility

Examples of application areas:

Mechanical engineering: In mechanical engineering, Axle holders DIN 15058 are used in a variety of machine types – from machine tools to production and packaging lines to conveyor systems. They enable the precise alignment of shafts and axles, which is essential for the correct functioning of the machines.

Robotics and automation: In robotics and automation technology, precise movements and positionings are fundamental. Axle holders contribute to the precise control and guidance of mechanical motion sequences here, improving the efficiency and accuracy of automated processes.

Shipbuilding: Axle holders are also used in shipbuilding to ensure the necessary stability and safety by keeping axles and shafts in place, which is especially important when transmitting large forces and with high stresses.

Wind turbines: In wind turbines, axle holders play a crucial role in ensuring the correct axle positioning within the drivetrain. They support the precise alignment of shafts necessary for energy generation and significantly contribute to the efficiency and longevity of the system by reducing the stress on the mechanical components.

Textile industry: In textile processing, axle holders are used to secure the axles and shafts of spinning and weaving machines. These applications require high precision to ensure the uniformity and quality of textile products. Axle holders provide the necessary stability and precision of moving parts in this sector, enabling consistent production quality.

Compatibility:

The compatibility of axle holders DIN 15058 extends well beyond the application areas, as they are specifically designed to work in systems with other DIN-standardized components and elements. This ensures easy integration into existing constructions and easy interchangeability. The universal nature of DIN standards facilitates planning, installation, and maintenance for engineers and technicians, ensuring that the components work together without extensive adjustments or modifications. Overall, the wide application range and high compatibility of axle holders DIN 15058 allow versatile use in industrial and technical fields, where precision, reliability, and safety are of utmost importance.

4. Advantages and Benefits

Axle holders according to DIN 15058 offer a variety of advantages and benefits, making them indispensable components in many mechanical and industrial applications:

Precision and stability: These axle holders ensure precise positioning and fixation of axles and shafts, allowing for stable and precise transmission of rotational movements and forces. This reduces unwanted slipping and misalignments that could lead to machine damage.

Easy integration: Thanks to the standardized dimensions according to DIN 15058, compatibility with other standardized components is ensured. This facilitates planning, installation, and replacement without the need for extensive adjustments. It saves time and costs during assembly and maintenance.

Reduced wear: By stabilizing the axles and shafts, axle holders minimize mechanical wear. This leads to an extended lifespan of the affected components and reduces maintenance costs and downtime.

Versatile applications: The universal application of axle holders means they are used in various industries such as mechanical engineering, the automotive industry, robotics, wind power, the textile industry, and many others. This versatility makes them a flexible solution for many mechanical challenges.

Increased safety: By securely fixing the axles and shafts, axle holders prevent unwanted loosening or slipping, which is particularly important in safety-critical applications. This contributes to the overall operational safety of machines and systems.

Improved efficiency: The precise alignment and fixation of axles and shafts ensure smoother and more efficient transmission of forces and movements. This optimizes the overall performance of machines and systems. These advantages make axle holders according to DIN 15058 indispensable components that significantly contribute to the performance, safety, and longevity of mechanical systems.

5. Assembly and Installation

The assembly and installation of axle holders according to DIN 15058 require careful planning and precise execution to ensure optimal functionality and longevity:

Preparation:

- Cleaning: Ensure the mounting surface and all parts are free from dirt, grease, and other contaminants.

- Inspection: Check all parts for damage or deviations from specified dimensions and tolerances.

Positioning:

- Alignment: Position the axle holder exactly according to the specifications and drawings. Correct alignment of the axle holders is crucial for precise fixing.

- Fixing markers: Use markings or positioning aids if necessary to ensure the exact position.

Attachment:

- Screws and Bolts: Use matching screws or bolts according to DIN standards. Tighten them evenly and crosswise to avoid tension.

- Torque: Observe the recommended torques for the fastening elements to ensure a solid and permanent fixation.

Inspection:

- Checking: After assembly, all fasteners should be checked for tightness. Re-checking after a few hours of operation can help detect and tighten loose elements early.

- Measurement Technology: For critical applications, the use of measurement technology to check alignment and fixation can be helpful.

Lubricants:

- Lubrication: If necessary, lubricants should be applied to the designated areas to ensure the mobility of the axles and shafts and to protect against corrosion.

Securement:

- Securing measures: Use retainers like locking washers or locking nuts to prevent unintentional loosening of fasteners.

Regular maintenance:

- Inspections: Conduct regular inspections to ensure the tightness and correct function of the axle holders.

- Adjustments: If necessary, adjustments should be made to ensure optimal performance and safety.

By carefully following these steps, a reliable and durable installation of axle holders according to DIN 15058 can be achieved, contributing to the optimal function and high operational safety of the entire mechanical system.

6. Safety instructions

Preparation and planning: Ensure that all personnel working with the axle holders are adequately trained and familiar with the relevant safety guidelines and manuals.

Tools: Use only appropriate and well-maintained tools. Defective or unsuitable tools can complicate assembly and lead to accidents.

Personal protective equipment: Wear protective gloves to protect your hands from cuts and bruises. Wear safety glasses to protect your eyes from sparks, dust, and foreign objects.

Inspection and maintenance: Conduct regular inspections to ensure that the axle holders are secure and show no signs of wear or damage. Check the fasteners after a few operating hours and tighten them if necessary to prevent loosening.

Documentation: Keep a written record of all maintenance and inspection measures. This helps to demonstrate compliance with safety standards and plan future maintenance work.